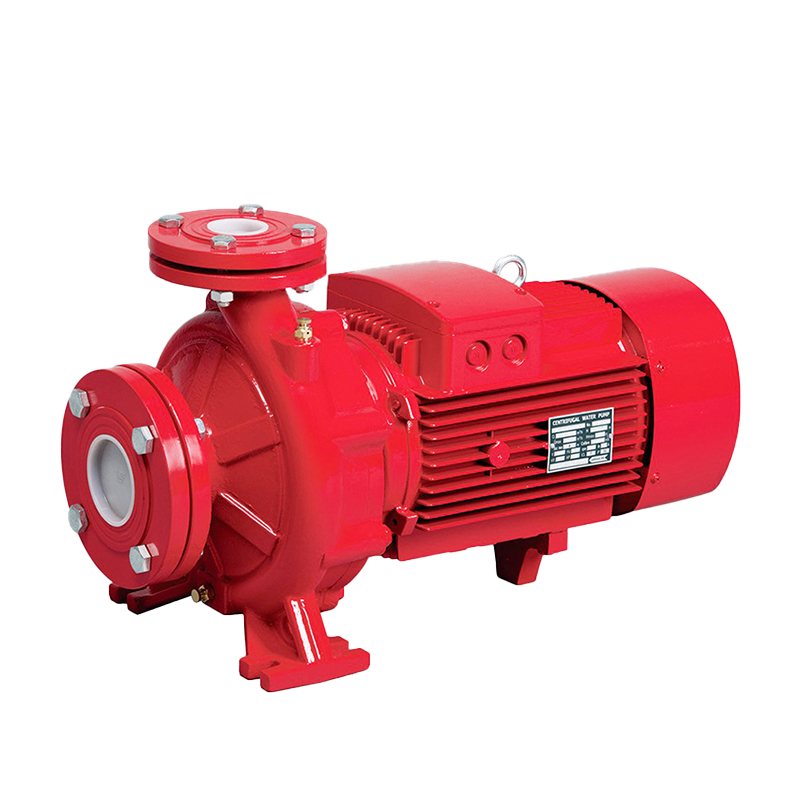

PSM End Suction Centrifugal Pump

Introduction:

The end suction centrifugal pump is a versatile device widely used in various industries for fluid handling applications. In this article, we will delve into the working principles, features, and applications of this efficient pump, highlighting its significance in fluid transportation.

Understanding the End Suction Centrifugal Pump:

The end suction centrifugal pump is a type of centrifugal pump that draws fluid through a single inlet located at the end of the pump casing. It utilizes centrifugal force to impart energy to the fluid, enabling efficient transportation and circulation.

Working Principles:

a. Impeller Action: The pump's impeller rotates rapidly, creating a centrifugal force that propels the fluid radially outward.

b. Conversion of Kinetic Energy: As the fluid moves through the impeller, its kinetic energy increases, generating the necessary pressure for efficient fluid transportation.

c. Single Inlet Design: The end suction configuration allows the pump to draw fluid from a single inlet, simplifying the installation and operation process.

Key Features and Advantages:

a. Versatility: End suction centrifugal pumps can handle a wide range of fluids, including water, chemicals, and petroleum products, making them suitable for diverse applications.

b. Easy Maintenance: These pumps have a simple design and fewer moving parts, resulting in easy maintenance and reduced downtime.

c. Cost-Effective: Their efficient operation, coupled with low maintenance requirements, makes them a cost-effective choice for fluid handling needs.

d. Compact Size: The compact design of end suction centrifugal pumps enables easy installation, even in space-constrained environments.

e. High Efficiency: With optimized impeller designs and hydraulic performance, these pumps deliver high efficiency and ensure maximum fluid flow rates.

Applications of End Suction Centrifugal Pumps:

a. Water Supply and Treatment: These pumps are widely used in municipal water supply systems, irrigation, and water treatment plants.

b. HVAC Systems: End suction centrifugal pumps play a crucial role in heating, ventilation, and air conditioning (HVAC) systems, facilitating the circulation of chilled water or hot water.

c. Industrial Processes: They are employed in various industrial sectors for fluid transfer, including manufacturing, chemical processing, and power generation.

d. Fire Protection Systems: End suction centrifugal pumps are integral components of fire protection systems, ensuring an adequate water supply for firefighting purposes.

Maintenance and Safety Considerations:

Regular maintenance, including inspection, lubrication, and cleaning, is essential to ensure optimal performance and prolong the pump's lifespan. Adherence to safety guidelines and compliance with industry standards are crucial for safe operation.

Conclusion:

The end suction centrifugal pump is a reliable and efficient solution for fluid transportation across a wide range of applications. Its versatile design, ease of maintenance, and high-performance characteristics make it an indispensable component in various industries, ensuring efficient fluid handling and reliable operation.

Question :What is your payment terms?

Answer :30%T/T, L/C,West Union, .etc.

Question:Do u have your own designers and engineers?

Answer:We are professional centrifugal pump supplier, we have engineers and we are the first enterprise to make high temperature submersible pump in Zhejiang Province.

Question:How long is your warranty?

Answer:3 years after buying our pump.

Question: What are the impeller materials of end suction centrifugal pumps

Answer:Cast iron, Brass or AISI 304

Question: How is the quality of the motor

Answer: We use YE3 high efficient motor,with protection IP55 class F.

Question:How can I get the price ?

Answer:Pls let us know power,flow capacity ,head and quantity,we can give u price according to your requiremnt.

English

English عربى

عربى

Fire Pump and System

Fire Pump and System Split Case Pump

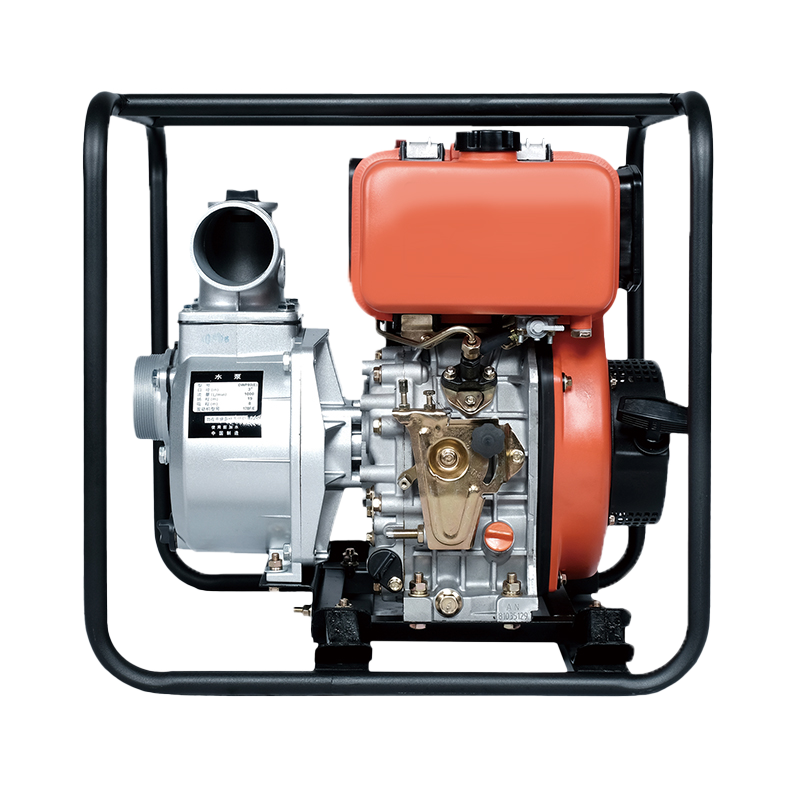

Split Case Pump Engine and Pump

Engine and Pump Long Shaft Pump

Long Shaft Pump Multistage pump

Multistage pump Water Supplier System

Water Supplier System Sewage Pump

Sewage Pump Industrial Pump

Industrial Pump Self-Priming Pump

Self-Priming Pump Inline Pump

Inline Pump Domestic Pump

Domestic Pump Electric Motor

Electric Motor Borehole Pump

Borehole Pump